-

-

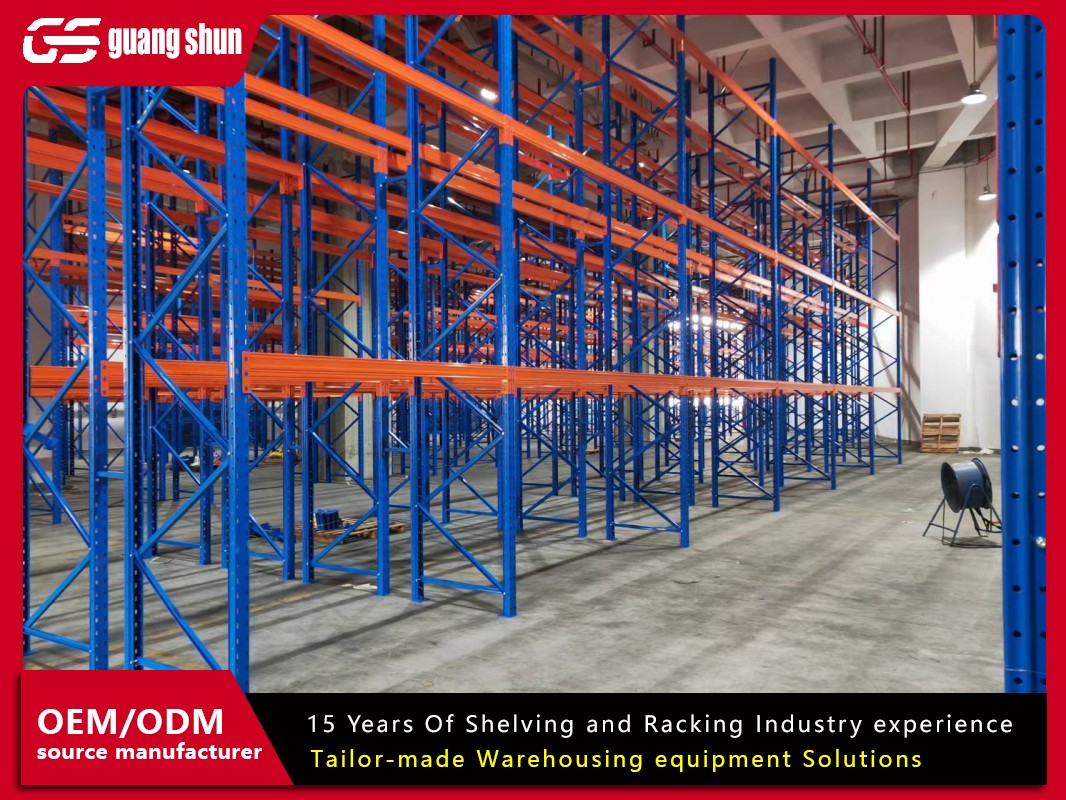

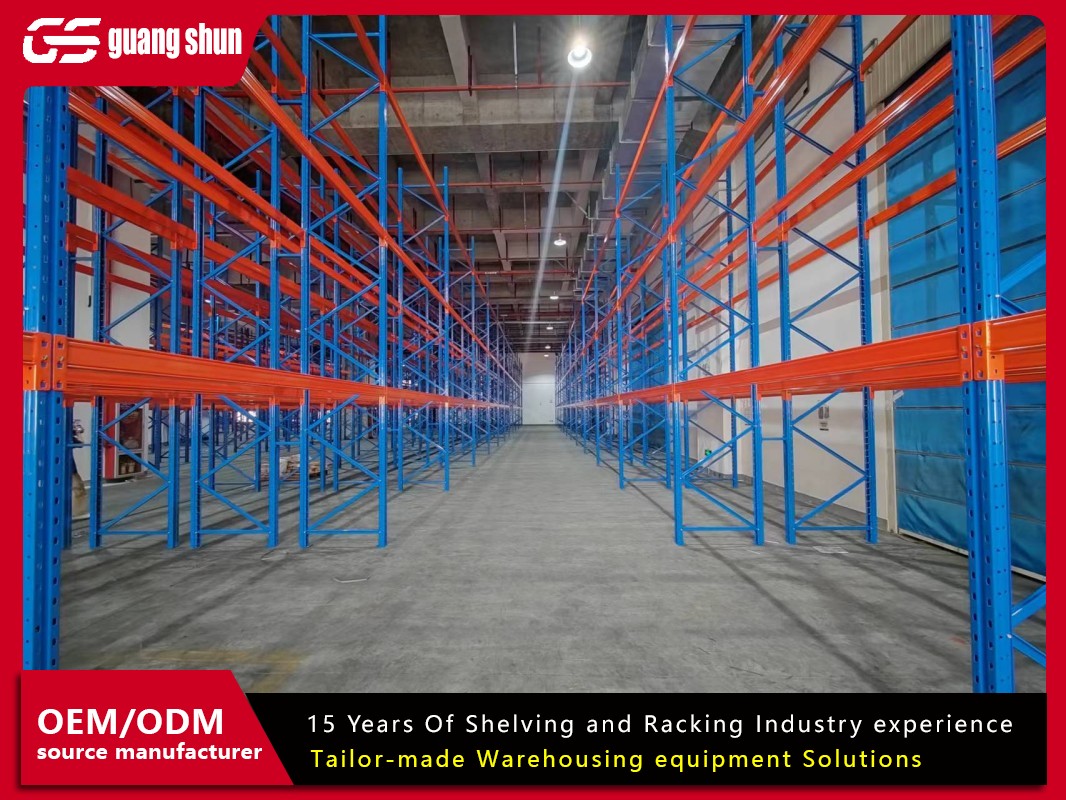

Pallet Racking

- Double-deep-pallet-racking Drive-in Racking Heavy Duty Shelves Narrow Aisle Racking

-

Mezzanine Rack

- Storage Loft Platform Mezzanine Shelves Rack Supported Platform Heavy Duty Mezzanine Warehouse Mezzanines Floor

-

Storage Racks

- Medium Shelves Flow(dynamic) Rack Shelving Cantilever Shalving Pallet Shuttle Racking Shelves for placing molds

-

Others

- Storage Cage Ladder Cart Stacking rack

-