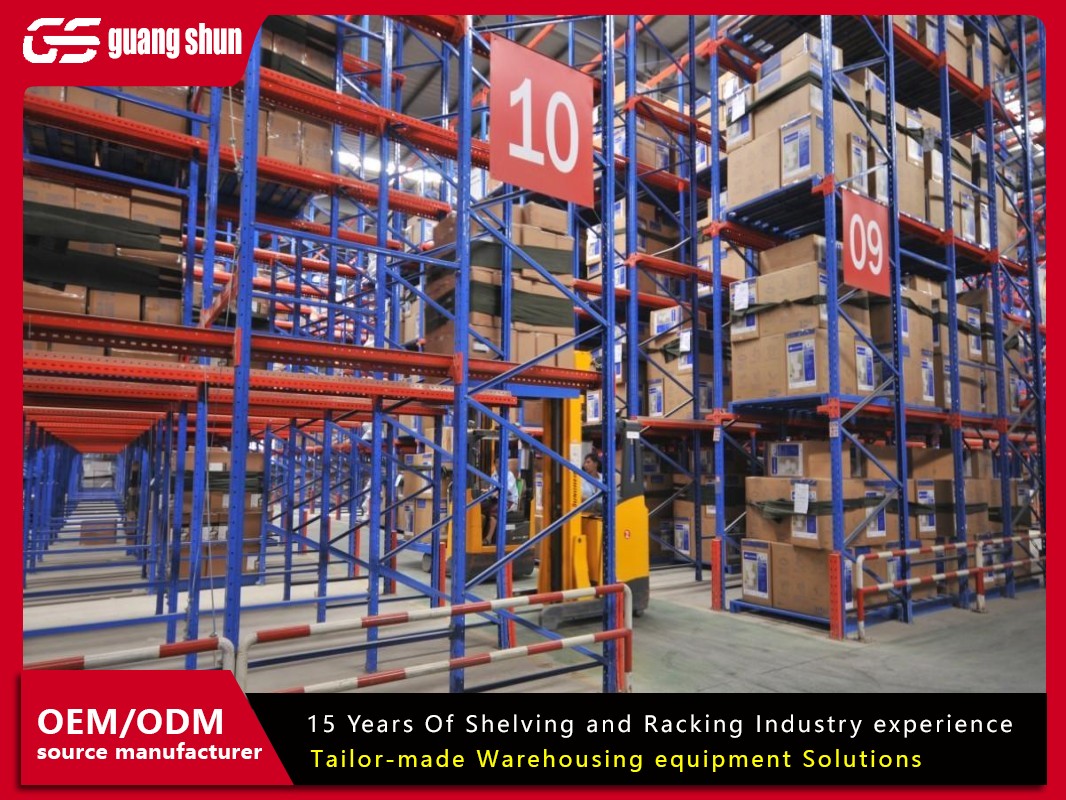

Drive-in racking is a racking system suitable for storing large quantities of similar products, and is often used in warehouses and distribution centers that require a lot of storage space. Drive-in racking are designed to maximize the utilization of storage space, storing goods in aisles one after another without having to set up a storage location for each item.

Drive-in racking work by driving forklifts directly into the rack aisles and storing the goods in the appropriate location. There are no partitions between the goods, so forklifts need to be operated with extra care to avoid hitting other goods. This design makes the racking system more suitable for storing goods of the same size and weight.

The advantages of drive-in racking include:

1. Maximizing storage space utilization: By reducing the space between aisles and aisles, more goods can be stored.

2. Improving access speed: Drive-in racking can access goods faster than traditional warehouse storage systems.

3. Suitable for large-volume storage: Suitable for occasions where a large number of similar products need to be stored.

However, drive-in racking also have some limitations:

1. Not suitable for warehouses that need to frequently access goods, because other goods need to be removed to take out the desired goods.

2. Forklifts need to be operated with extra care to avoid collisions with other goods and damage.

3. Only suitable for storing goods of the same size and weight, not suitable for storing a variety of products.

In general, Drive-in racking is a shelf system suitable for storing large quantities of similar products. Its design can effectively maximize the utilization of storage space and improve access speed. It is suitable for warehouses and distribution centers that need to store large quantities of goods.

Technical Specifications of Drive-In Racking System

A detailed breakdown of parameters for logistics warehouses, cold storage, and industrial applications:

1. Basic Structural Parameters

| Parameter | Specifications |

|---|

| Racking Type | Drive-in (push-back) system, requiring forklifts to enter lanes for load access. |

| Column Material | High-strength cold-rolled steel (Q235/SS400), thickness 2.0-3.0mm, anti-corrosion coating (powder-coated/hot-dip galvanized). |

| Beams & Rails | Load-bearing beams with reinforced C-section steel rails; 800kg-3000kg per tier. |

| Height Adjustment | Adjustable tier spacing (typically in 75mm increments) for flexible cargo height adaptation. |

2. Design Parameters

| Parameter | Specifications |

|---|

| Lane Width | Customized based on forklift type: 1600-2200mm minimum (wider for counterbalance forklifts, narrower for VNA). |

| Storage Depth | 2-5 pallet positions per side, deep-lane design with 60%-75% space utilization. |

| Racking Height | Typically ≤12 meters (subject to warehouse ceiling height, fire codes, and forklift lift capacity). |

| Pallet Compatibility | Supports Euro (1200×800mm) or U.S. (1200×1000mm) pallets; pallet openings 50-100mm wider than pallets. |

3. Load Capacity & Safety

| Parameter | Specifications |

|---|

| Dynamic Load/Tier | 800kg-2500kg per tier (heavy-duty designs exceed 3000kg). |

| Seismic Compliance | Meets GB/T 28576-2012 standards; foundation design based on geological reports. |

| Safety Features | Column guards, load stoppers, and lane-end impact barriers. |

4. Applications & Limitations

| Parameter | Details |

|---|

| Ideal for | High-volume, low-SKU, low-turnover goods (e.g., beverages, chemicals, bulk food). |

| Not Recommended | High-turnover SKUs or mixed-SKU storage (lower access efficiency). |

| Environmental Requirements | Floor flatness tolerance ≤±10mm; humidity ≤80%; avoid corrosive environments. |

5. Installation & Maintenance

| Parameter | Details |

|---|

| Installation Time | ~3-5 days per 1,000 pallet positions (varies by site complexity). |

| Maintenance | Inspect column alignment, bolt tightness, and beam deformation biannually. |

| Lifespan | 10-15 years under normal conditions (extendable with regular maintenance). |

6. Comparison with Other Systems

| Parameter | Drive-In Racking | Selective Pallet Racking | Shuttle Racking |

|---|

| Space Utilization | 60%-75% | 45%-55% | 70%-85% |

| Access Efficiency | Low (LIFO) | High (FIFO/LIFO) | Medium-High (semi-automated) |

| Cost | Medium | Low | High |

Key Recommendations:

- Ideal for high-volume, single-SKU warehouses with low turnover rates.

- Ensure forklift operators are well-trained to minimize collision risks.

- Provide warehouse layouts, cargo dimensions, and turnover data for customized designs.

(Specifications are general guidelines; adjust based on project requirements.)

Drive-in racking is the simplest and most affordable high-density storage method. It is comprised of multiple racks with a series of lanes accessed by forklifts to deposit or retrieve pallets. Compared to conventional pallet racking, this solution notably increases storage capacity.

2. How does drive-in racking work?

Drive-through pallet racking involves the forklift loading pallets on one side and unloading pallets on the opposite side. In this system, the truck uses rails to unload and load product after driving into the racks themselves.

3. What are the advantages of Drive-in racking?

- High space utilization: The drive-in racking is compact in design, which can better utilize the space in the computer room and save space costs.

- Good cooling effect: The design of the drive-in racking can effectively improve the heat dissipation effect, maintain the normal operating temperature of the equipment, and extend the service life of the equipment.

- Convenient maintenance: The design of the drive-in racking makes the equipment easier to maintain, and it is easier to enter the rack for maintenance operations during maintenance.

- Higher security: The drive-in racking can be equipped with locks to ensure the safety of the equipment and prevent illegal entry or unauthorized operation.

- Increase equipment density: The drive-in racking can accommodate more equipment, increase the equipment density of the data center, and improve work efficiency.

- Strong flexibility: The drive-in racking can be customized according to actual needs to meet the needs of data centers of different sizes, and has strong flexibility and adaptability.

4. What are the disadvantages of a drive-in racking?

- Large space occupation: Drive-in racking require sufficient space to enter the cargo storage area, which may lead to inefficient use of the warehouse's internal space.

- Slow loading and unloading speed: Drive-in racking require a forklift to enter the rack before loading and unloading goods. Compared with other types of racks, the speed of loading and unloading goods may be slower.

- High requirements for forklifts: Drive-in racks have relatively high requirements for forklift operation, requiring high driving skills and operating proficiency.

- Not suitable for storing a large number of different types of goods: Due to the relatively complex operation of drive-in racking, it is not suitable for storing a large number of different types of goods because it is difficult to find and take out goods quickly.

- High cost: Drive-in racking are more expensive than other types of racks, including installation, operation and maintenance costs.

5. What is the purpose of a drive-in racking?

The main advantages of Drive in or Drive through compact pallet racking systems are their maximum compaction and optimisation of space and perfect stock control. Space optimization above 80%. Low maintenance and low assembly costs make this system one of the most cost-effective systems.

6. What is the difference between drive in racking and selective racking?

Drive-In Racking: Limited selectivity but compensates with high space optimization. Pallet Flow Racking: Offers direct access to each pallet, enhancing selectivity. Selective Racking: Provides direct access to each pallet, ensuring high selectivity and adaptability.