Factory racking, also known as industrial racking or warehouse racking, is a system of storage shelves and racks that are used to efficiently store and organize goods in a factory or warehouse setting. These racking systems are essential for maximizing storage space, improving inventory management, and increasing productivity in industrial environments.

There are various types of factory racking systems available, each with its own unique features and benefits. Some of the most common types of factory racking include:

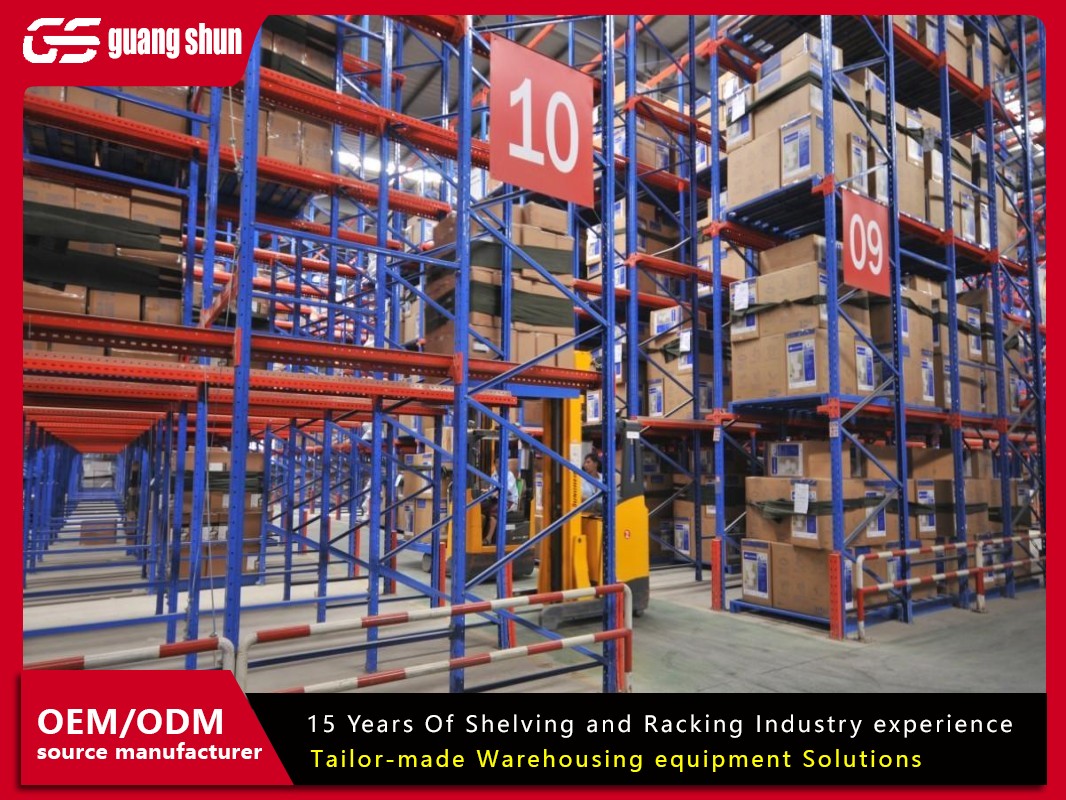

1. Selective Pallet Racking: This is the most common type of factory racking and allows for easy access to all stored goods. Pallets are stored on horizontal beams that are adjustable and can be customized to fit different pallet sizes.

2. Drive-in Racking: This type of racking is ideal for storing large quantities of the same product. Pallets are loaded and retrieved from the same side, making it a high-density storage solution.

3. Cantilever Racking: Cantilever racking is designed for storing long, oversized, or irregularly shaped items such as lumber, pipes, or furniture. The shelves are open and adjustable to accommodate different sizes of goods.

4. Push Back Racking: This type of racking uses a last-in, first-out (LIFO) storage system, where pallets are pushed back along inclined rails. It is an efficient way to store multiple SKU's with varying quantities.

5. Mezzanine Racking: Mezzanine racking is a two-tier storage system that utilizes the vertical space of a warehouse by creating a platform on top of existing racking. It is ideal for creating additional storage space without expanding the footprint of the warehouse.

Factory racking systems are typically made from steel or other durable materials to withstand heavy loads and ensure the safety of stored goods. They can be customized to fit the specific needs of a facility, including size, weight capacity, and layout. Some factory racking systems also come with additional features such as wire mesh decking, pallet supports, and safety accessories to enhance functionality and efficiency.

Benefits of factory racking systems include

1. Maximizing Storage Space: Factory racking systems are designed to make the most efficient use of available storage space, allowing for higher storage density and increased capacity.

2. Improved Organization: By having a systematic storage system in place, goods can be easily located and retrieved when needed, reducing the time and effort required to manage inventory.

3. Increased Productivity: With goods stored in an organized manner, warehouse operations can be streamlined, resulting in faster order fulfillment and improved overall productivity.

4. Safety and Durability: Factory racking systems are built to withstand heavy loads and are designed with safety features to prevent accidents and injuries in the workplace.

5. Cost-Effective: Investing in a factory racking system can lead to cost savings in the long run by maximizing storage space, reducing damage to goods, and improving overall efficiency.

Overall, factory racking systems play a crucial role in the smooth operation of industrial facilities by providing a structured and efficient storage solution for goods. Whether it's selective pallet racking for easy access to inventory or drive-in racking for high-density storage, there are various options available to meet the unique needs of different industries. Investing in a quality factory racking system can help optimize warehouse operations, improve inventory management, and ultimately drive business success.