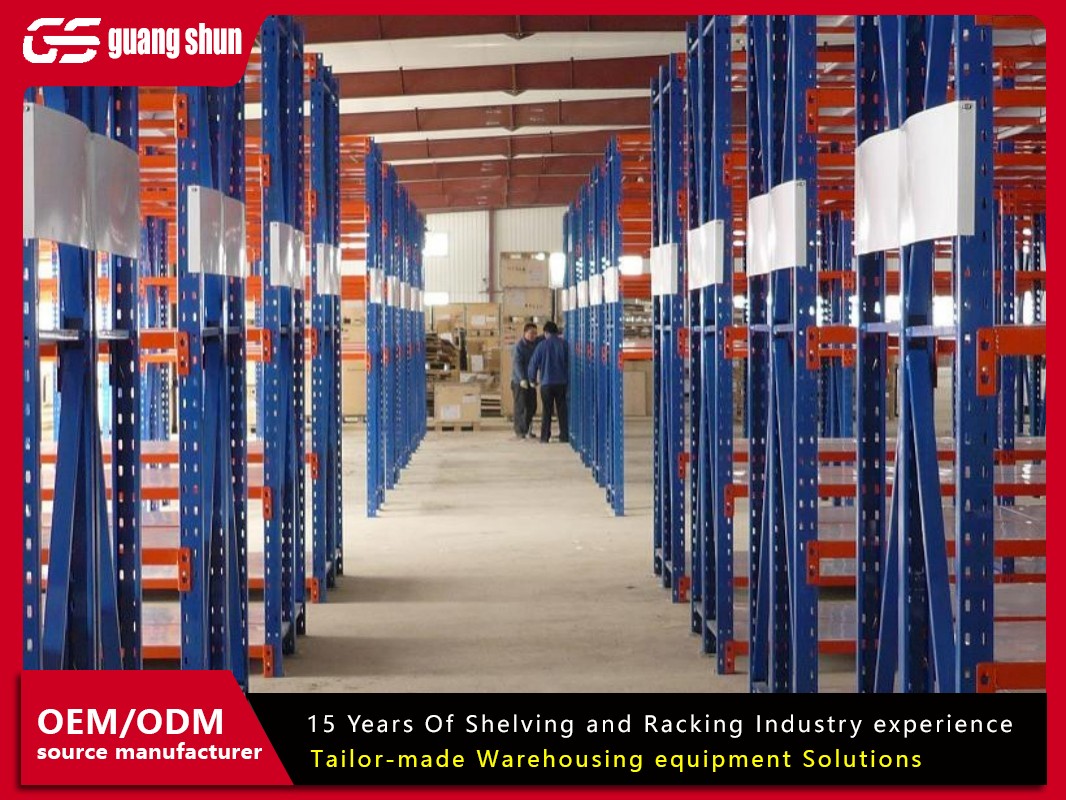

Heavy duty shelves are a must-have for any warehouse or industrial setting. These shelves are designed to hold heavy loads and provide a strong and durable storage solution for your products. Let's explore the features and benefits of heavy duty shelves in more detail.

One of the key benefits of heavy duty shelves is their robust construction. Made from high-quality materials such as steel or aluminum, these shelves are built to last and withstand the weight of heavy items. This makes them ideal for storing large and bulky items in an organized manner.

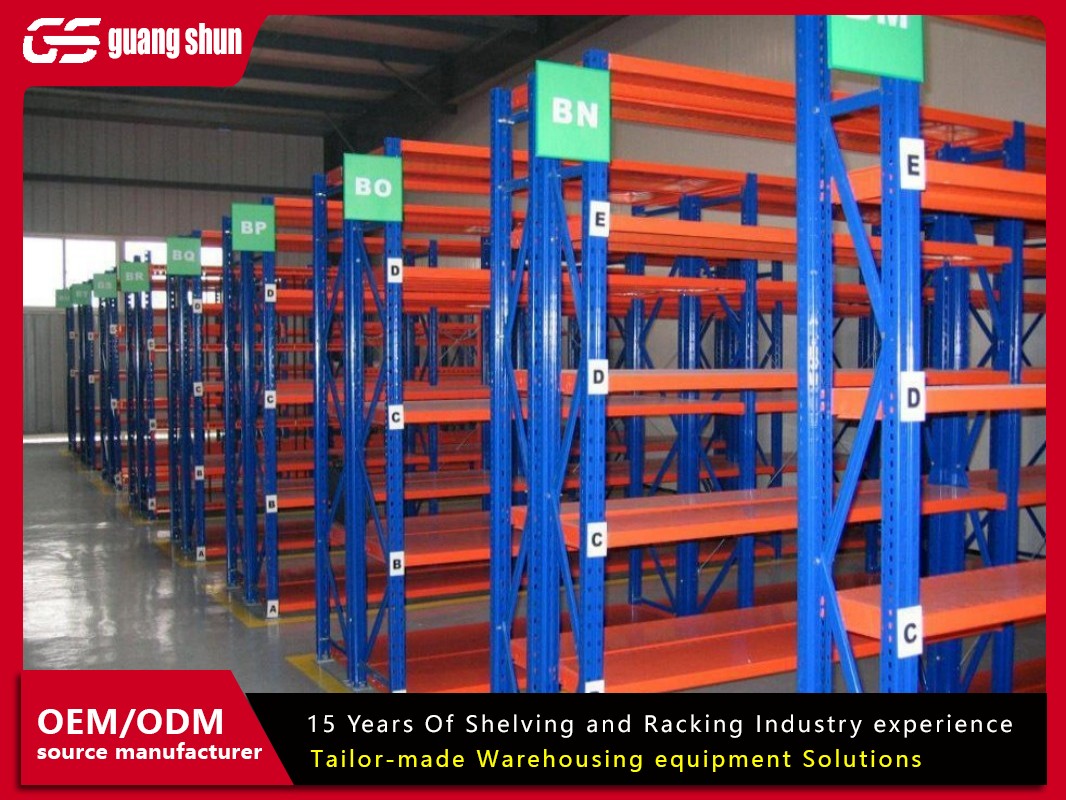

Another advantage of heavy duty shelves is their versatility. They come in a variety of sizes and configurations to suit different storage needs. Whether you need to store pallets, boxes, or other items, there is a heavy duty shelf that can accommodate your requirements.

In addition, heavy duty shelves are easy to assemble and adjust. Many models feature adjustable shelves that can be easily repositioned to create custom storage solutions. This means you can optimize your warehouse space and increase storage efficiency.

Furthermore, heavy duty shelves promote safety in the workplace. By keeping heavy items off the floor and organized on shelves, you can reduce the risk of accidents and injuries. This is especially important in busy warehouse environments where safety is a top priority.

Overall, heavy duty shelves offer a reliable and efficient storage solution for industrial settings. Their durability, versatility, and safety features make them a valuable investment for any business looking to improve their storage capabilities.

In conclusion, heavy duty shelves are a key component of a well-organized and efficient warehouse. Their sturdy construction, versatility, and safety features make them an essential storage solution for heavy items. If you are looking to optimize your warehouse space and improve storage efficiency, consider investing in heavy duty shelves today.

Q: What are the best heavy duty shelves for garages?

F: The best garage heavy duty shelves need to take into account the bearing capacity, durability, and space utilization rate. For example:

WORKPRO 5-Tier Metal Shelving: Each layer can bear a weight of 800 pounds, and the total capacity is 4000 pounds. It is made of rust-resistant powder-coated metal, which is suitable for storing tools and equipment.

HyLoft Steel Wall Shelving: It can bear a weight of 200 pounds per layer, and its low and compact design saves space, making it suitable for wall installation.

StoreYourBoard 2-Pack Shelves: Each layer can hold 200 pounds, and it comes with hooks for hanging bicycles and other items, which is suitable for flexible storage.

When choosing, you need to pay attention to the material (such as cold-rolled steel), installation method (bolt fixing or tool-free assembly), and additional functions (such as anti-skid mats).

Q: How to install heavy duty shelves safely?

F: The key steps for safely installing heavy duty shelves include:

Location of wall columns: Use a detector to find wooden or concrete wall columns, and make sure the bracket is fixed on the load-bearing structure.

Use a template and a level: For example, the installation template and bubble level provided by WORKPRO to ensure the horizontal alignment of the bracket.

Enhancement measures: Add diagonal supports or metal angle brackets to increase stability, especially when storing overweight items.

Hardware selection: Prioritize the use of expansion bolts (for concrete walls) or long wooden screws (for wooden walls), to avoid relying solely on drywall anchors.

Q: How to build a heavy duty shelf?

F: The key points of heavy duty shelves:

Material selection: It is recommended to use hardwood (such as oak) or plywood of 18mm or more, paired with steel brackets or metal corner braces.

Structural design: The frame should include vertical supports and horizontal beams, and wooden strips can be installed under the layers to prevent bending.

Load-bearing optimization: It is recommended that the depth of each layer be 18-24 inches, and the layer height should be adjusted according to the size of the items, and ensure that the load-bearing per square foot does not exceed the design value (e.g., 200 pounds)39.

Safety reinforcement: Use L-shaped brackets or cross supports, and ensure that the shelves are fixed to the wall through multiple anchor points.

Q: What is the weight capacity of heavy duty shelves?

F: The load-bearing capacity of heavy duty shelves varies depending on the design and materials:

Industrial-grade metal shelves (such as REIBII 3000LBS): Single layer can hold up to 600 pounds, and the total load-bearing capacity is 3000 pounds, which is suitable for warehouse use.

Home steel tier rack (such as Origami folding shelf): 250 pounds in a single layer without wheels, and 75 pounds when equipped with wheels.

Custom wooden frame: When using 2x4 wood and fixing it with bolts, it can carry more than 400 pounds on a single layer.

Note: The actual load-bearing should be evenly distributed to avoid concentrating and stacking sharp or damp items.

Q: What are the best heavy duty shelves for industrial use?

F: For industrial scenarios, we recommend the following types:

Pallet Racking System: Such as the Drive-In type, which supports high-density storage and is suitable for large quantities of uniform goods.

Heavy duty steel shelves: such as the metal tier shelves recommended by Cadre, which can be customized in size and equipped with wire mesh shelves to enhance ventilation.

Modular shelves (such as HOMEDANT 5-Tier): The height of the layers can be adjusted, and they can support 771 pounds per layer, which is suitable for flexible storage needs.

Industrial shelves must comply with OSHA safety standards, and their structural integrity should be regularly checked to avoid overloading.