Project Background and Requirements Analysis

A Chinese logistics company plans to establish a 12,000 square meter overseas warehouse in Jakarta, Indonesia, primarily for storing e-commerce goods, industrial spare parts, and fast-moving consumer goods. The warehouse must meet the following core requirements:

1. High Space Utilization: With a ceiling height of 7.2 meters, vertical space must be fully utilized to accommodate future business growth.

2. Categorized Storage: The warehouse needs to store both small, loose items (e.g., electronic components) and heavy palletized goods (e.g., machinery equipment), while supporting rapid turnover.

3. Operational Flexibility: The design must accommodate both manual picking and mechanized handling, aligning with local labor practices and equipment availability in Indonesia.

Solution: Collaborative Design of Mezzanine Shelving and Heavy-Duty Shelving

1. Mezzanine Shelving System – For Small and Medium-Sized Goods

· Structural Design:

A three-tier mezzanine shelving system is adopted, with a total height of 6.8 meters. The lower level features medium-duty shelving (load capacity: 500kg per level), while the upper levels consist of fully enclosed galvanized steel floors (load capacity: 800kg per square meter), expanding the total storage area to 2.5 times the original warehouse space.

· Functional Adaptation:

o The top level stores low-turnover spare parts, the middle level houses e-commerce small items (for manual picking), and the lower level accommodates medium-sized packaged goods.

o Staircases are embedded into the shelving aisles to save space, and electric lifting platforms (load capacity: 1 ton) are installed for bulk vertical transportation.

· Environmental Adaptation:

The floor surface is anti-slip treated, and the lighting system is integrated into the shelving columns with concealed wiring, meeting electrical safety standards for Southeast Asia’s high-temperature and high-humidity environment.

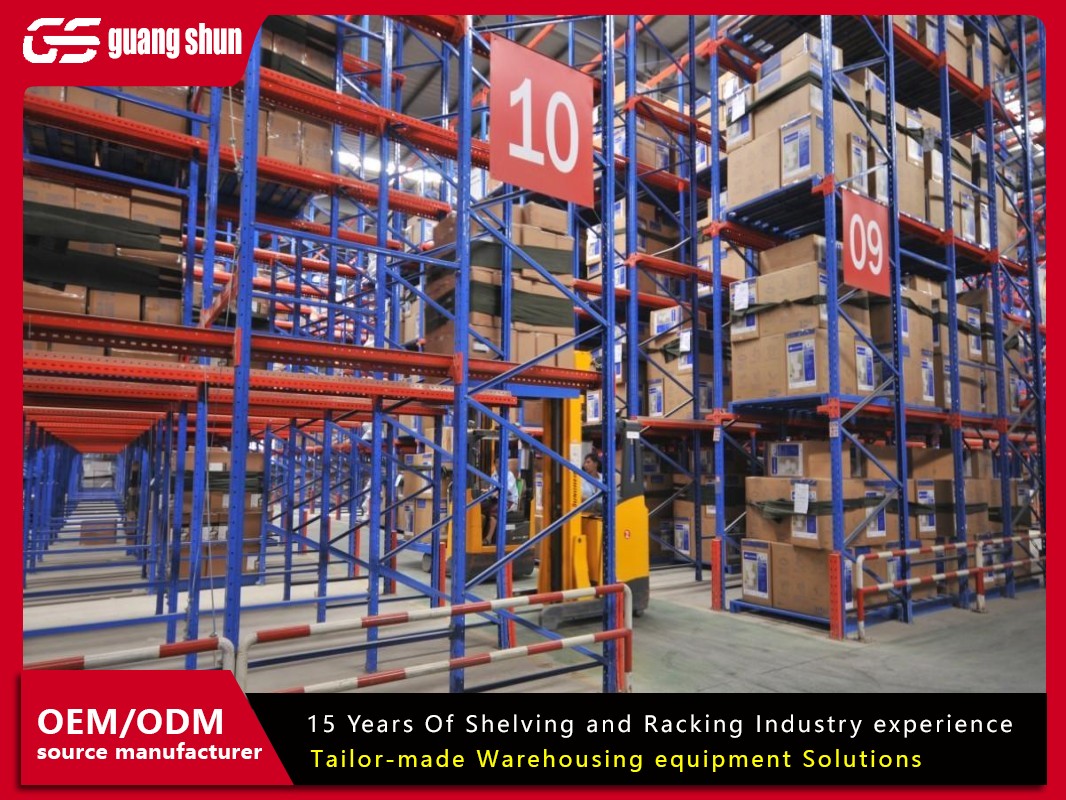

2. Heavy-Duty Shelving System – For Palletized Heavy Goods

· Shelving Selection:

Beam-type heavy-duty shelving is used, designed with four levels and five beams, supporting a load capacity of 1.5 tons per pallet. The shelving depth is 1.2 meters, compatible with standard pallets (1.2m × 1.0m). The total height is 6 meters, with 1.2 meters of overhead space reserved for ventilation and equipment movement.

· Layout Optimization:

o Aisle width is set at 3.5 meters to accommodate locally common counterbalance forklifts (load capacity: 2 tons), supporting "first-in, first-out" inventory management.

o The lower level stores heavy machinery, the middle level houses high-turnover goods, and a "hot-selling zone" is established near the outbound area to shorten picking paths.

· Safety Reinforcement:

Columns and beams are connected via plug-in structures, supplemented with safety pins and C-shaped beam clamps, ensuring seismic resistance suitable for Southeast Asia’s geological conditions.

Implementation Details and On-Ground Experience

1. Localization Adaptation:

o The shelving material is galvanized steel with anti-corrosion coating to withstand Indonesia’s high-salinity coastal air.

o Installation involves collaboration with local Indonesian construction teams, with pre-assembled modular components allowing on-site assembly in just 7 days, minimizing disruption to warehouse operations.

2. Intelligent Assistance:

o The mezzanine area is equipped with handheld PDA scanners linked to the Warehouse Management System (WMS), ensuring item location accuracy within 0.5 meters.

o The heavy-duty shelving area integrates pallet jacks and forklifts, with electronic labels guiding storage locations, reducing manual search time by 30%.

3. Cost and Efficiency Balance:

o The cost per square meter for mezzanine shelving is approximately 60% of standard shelving, but storage density increases by 3 times. Heavy-duty shelving achieves 2,000 storage locations through high-density layout, meeting a daily turnover of 500 pallets.

Project Outcomes

· Space Utilization: The total storage area increases from 12,000 square meters to 30,000 square meters, reducing unit storage costs by 40%.

· Operational Efficiency: Manual picking efficiency improves by 50%, and forklift handling efficiency reaches 120 pallets per hour.

· Scalability: The shelving system includes reserved interfaces for future integration with automated AGVs or shuttle systems, supporting intelligent upgrades.

Conclusion

Through the collaborative design of mezzanine shelving and heavy-duty shelving, this project not only addresses the diverse storage needs of the Indonesian overseas warehouse but also achieves low-cost, high-flexibility implementation through modular installation, localized material selection, and intelligent assistance. This case study provides a replicable planning template for similar warehouses in Southeast Asia, combining practicality and forward-looking design.