In today’s fast-paced logistics and supply chain landscape, efficient storage solutions are the backbone of successful warehouse operations. Among these solutions, storage racking stands out as a cornerstone technology, revolutionizing how businesses manage inventory, optimize space, and streamline workflows. This article explores the fundamentals of storage racking, its various types, benefits, and the reasons it has become the gold standard for modern warehousing.

1. Understanding Shelf Storage Racking

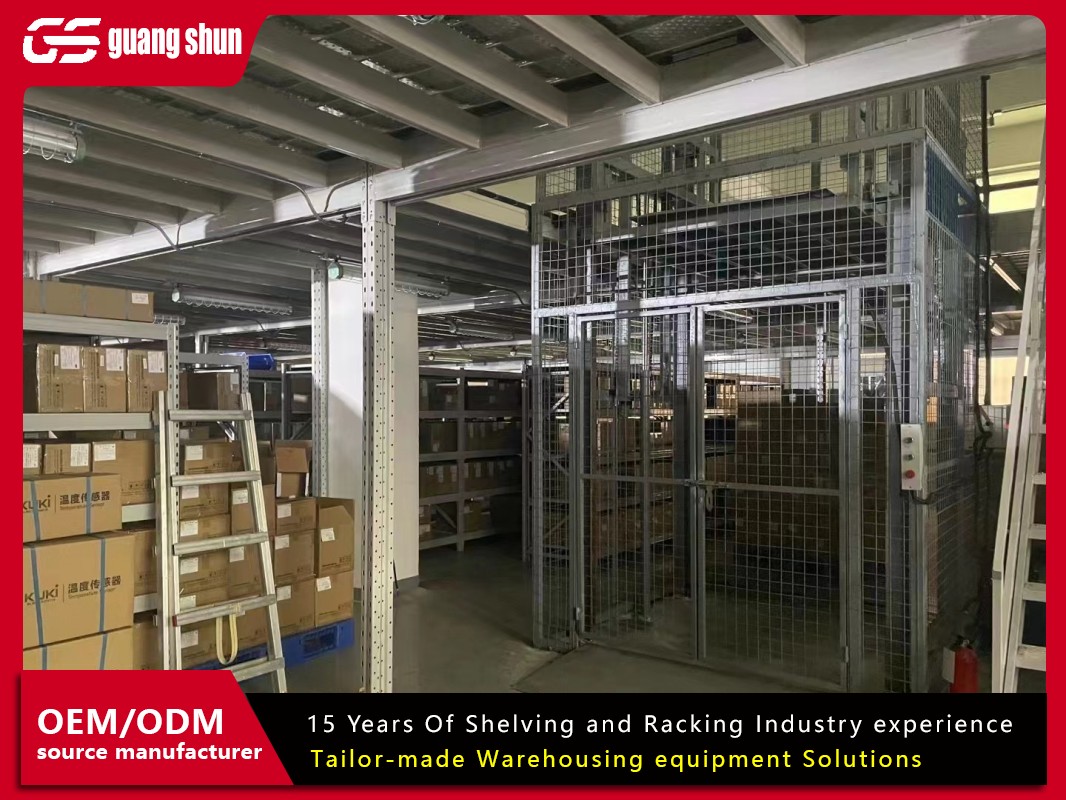

Storage racking refers to structured systems designed to store goods in an organized, accessible, and space-efficient manner. These systems consist of vertical frames, horizontal beams, and shelving units that create multiple levels for storing pallets, boxes, or individual items. Unlike traditional floor stacking, storage racking maximizes vertical space while ensuring load stability and ease of access.

Key components of storage racking include:

- Uprights: Vertical columns that form the framework.

- Beams: Horizontal supports that hold shelves or pallets.

- Shelves/Decking: Platforms for placing goods.

- Bracing: Cross-supports for structural integrity.

Modern systems, such as those offered by GS Rack, are engineered with high-grade steel and customizable configurations to meet diverse industry needs.

2. Types of Storage Racking Systems

The versatility of storage racking lies in its adaptability to different warehouse requirements. Below are the most common types:

2.1 Selective Pallet Racking

The most widely used system, selective racking, allows direct access to each pallet. Ideal for warehouses with high SKU diversity, it supports FIFO (First-In-First-Out) inventory management.

2.2 Drive-In/Drive-Through Racking

Designed for high-density storage, these systems enable forklifts to drive directly into the rack structure. They are perfect for bulk storage of homogeneous products, supporting LIFO (Last-In-First-Out) workflows.

2.3 Cantilever Racking

Used for long or irregularly shaped items (e.g., pipes, lumber), cantilever systems feature horizontal arms extending from vertical columns, eliminating the need for front columns for unobstructed access.

2.4 Push-Back Racking

This gravity-fed system uses inclined shelves and carts to store multiple pallets deep. When a new pallet is loaded, it pushes existing ones backward, optimizing space without sacrificing selectivity.

For specialized solutions, GS Rack offers tailored designs to match unique operational demands.

3. Why Storage Racking Dominates Modern Warehousing

3.1 Space Optimization

Warehouses face relentless pressure to reduce real estate costs. Storage racking systems, particularly high-density designs like drive-in racking, increase storage capacity by up to 80% compared to floor stacking. By utilizing vertical space, businesses can store more goods within the same footprint.

3.2 Enhanced Accessibility and Efficiency

Modern warehouses prioritize speed. Selective racking systems allow workers to retrieve items quickly, reducing picking times and improving order fulfillment rates. Automated systems, such as those integrated with GS Rack solutions, further enhance efficiency through real-time inventory tracking.

3.3 Scalability and Flexibility

As businesses grow, their storage needs evolve. Modular storage racking systems can be reconfigured or expanded without significant downtime. Adjustable beam heights and removable shelves accommodate changing inventory sizes.

3.4 Safety and Durability

Poorly organized warehouses pose safety risks. Storage racking systems minimize clutter, prevent load collapses, and comply with occupational safety standards. High-quality materials, like those used by GS Rack, ensure longevity even under heavy loads.

3.5 Cost-Effectiveness

While the initial investment in storage racking may seem substantial, the long-term savings are undeniable. Reduced labor costs, lower risk of product damage, and optimized space utilization contribute to a rapid ROI.

4. The Role of Technology in Modern Storage Racking

Innovation has elevated storage racking from static structures to smart solutions:

- Automated Storage and Retrieval Systems (AS/RS): Robotic shuttles and cranes work seamlessly with racking systems to automate picking and restocking.

- IoT Integration: Sensors monitor load weights, shelf conditions, and inventory levels in real time.

- WMS Compatibility: Warehouse Management Systems (WMS) sync with rack layouts to guide workers via digital interfaces.

Companies like GS Rack are pioneering these advancements, offering future-ready systems that align with Industry 4.0 standards.

5. Sustainability and Storage Racking

Environmental concerns are reshaping warehousing. Modern storage racking contributes to sustainability through:

- Material Efficiency: Recyclable steel structures reduce waste.

- Energy Savings: High-density systems lower the need for expansive facilities, reducing energy consumption.

- Longevity: Durable designs minimize replacement cycles.

GS Rack emphasizes eco-friendly manufacturing processes, aligning with global green logistics trends.

6. Choosing the Right Storage Racking Partner

Selecting a reliable supplier is critical. Key considerations include:

- Customization Options: Ability to tailor designs to specific needs.

- Compliance: Adherence to international safety standards (e.g., OSHA, FEM).

- After-Sales Support: Installation, maintenance, and training services.

GS Rack excels in these areas, providing end-to-end solutions trusted by leading global enterprises.

7. The Future of Storage Racking

Emerging trends include:

- AI-Driven Optimization: Machine learning algorithms predict inventory patterns and adjust rack layouts dynamically.

- Modular Robotics: Collaborative robots (cobots) working alongside human workers.

- Sustainable Materials: Bamboo-composite shelves and carbon-neutral manufacturing.

As warehouses evolve, storage racking will remain central to operational success, driven by innovators like GS Rack.

Storage racking is not merely a warehouse accessory—it is a strategic asset that drives efficiency, safety, and profitability. From selective pallet systems to AI-integrated designs, these solutions empower businesses to meet the demands of modern logistics. As the industry advances, partnering with experts like GS Rack ensures access to cutting-edge technology and sustainable practices, securing a competitive edge in an ever-evolving market.

By embracing innovative storage racking systems, warehouses can transform their operations, turning spatial constraints into opportunities for growth.